Polycarbonate (PC) sheets are celebrated for their versatility, and their structural variations are key to unlocking diverse applications across industries. Below is a detailed overview of the primary PC sheet structures, each engineered to enhance specific properties like strength, insulation, light diffusion, or weight efficiency.

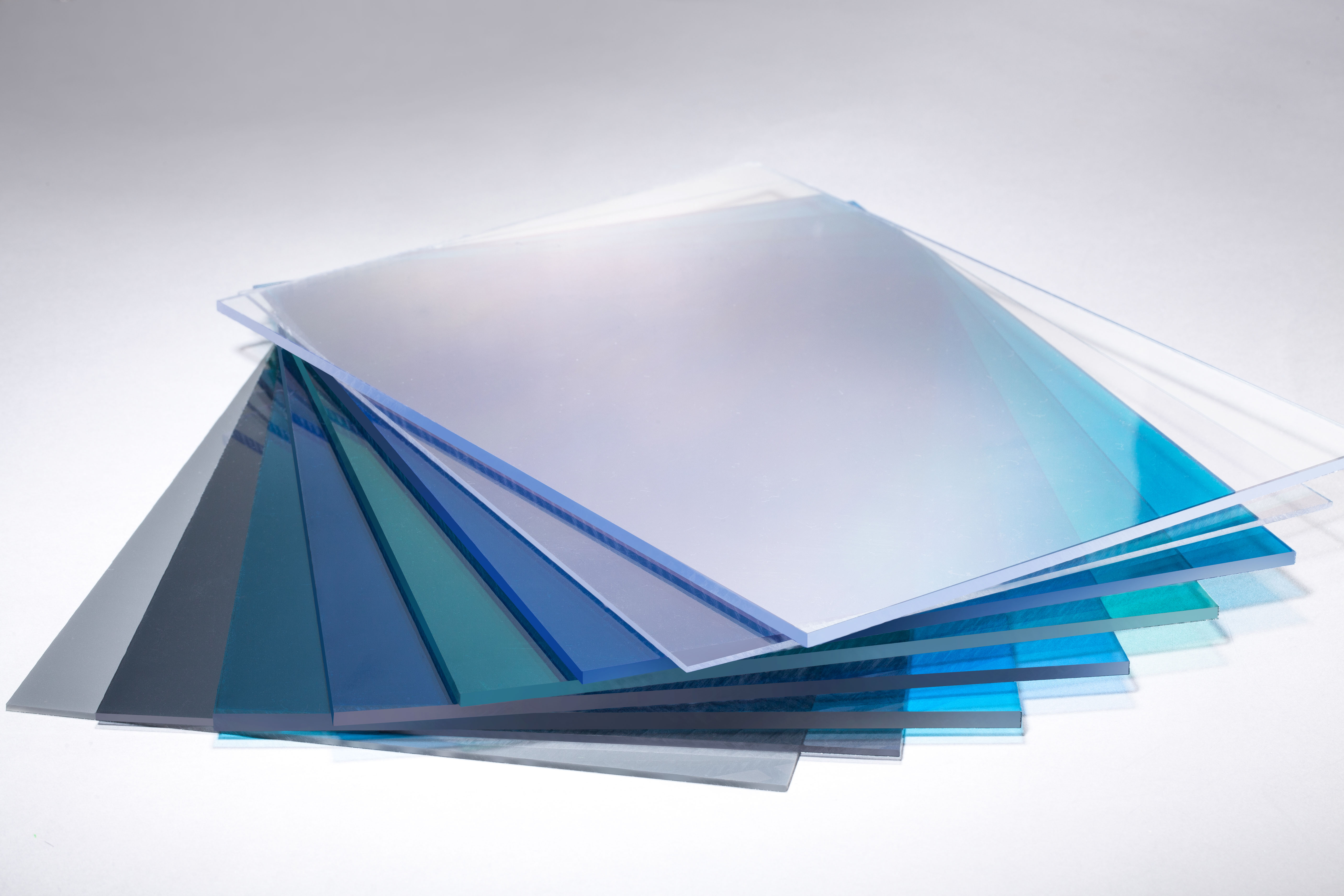

1. Solid PC Sheets

Solid PC sheets are the most basic structure, consisting of a single, uniform layer of polycarbonate. They are prized for their exceptional impact resistance—up to 250 times stronger than glass—while maintaining high transparency (up to 90% light transmission). Available in thicknesses from 0.5mm to 25mm, they offer rigidity and smooth surfaces, making them ideal for applications requiring clarity and durability. Common uses include safety glazing, machine guards, display cases, and protective barriers in high-traffic areas. Their simplicity also makes them easy to cut, drill, or thermoform, adapting to custom shapes.

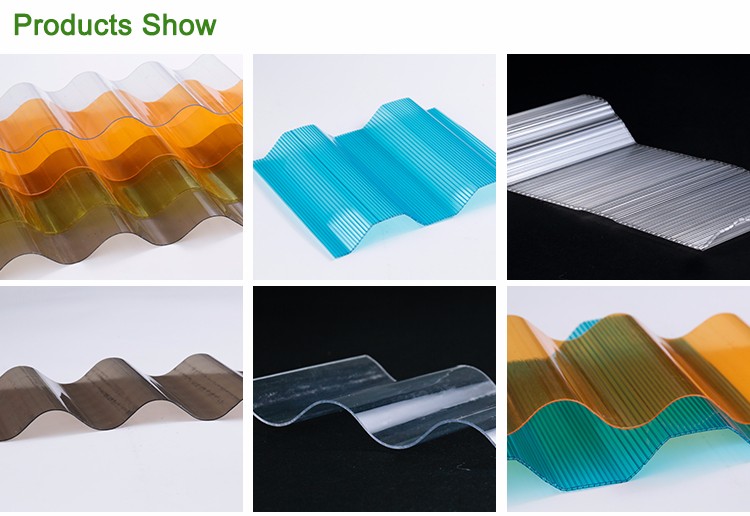

2. Corrugated PC Sheets

Corrugated PC sheets feature a wavy, ridged profile, inspired by traditional metal roofing but with PC’s lightweight and flexible advantages. The corrugation adds structural rigidity without increasing thickness, balancing strength and weight. This design enhances water runoff, making them perfect for roofing in agricultural buildings, carports, or sheds. They also excel in cladding for walls, as their shape allows for overlapping installation, ensuring weather resistance. Thicknesses range from 0.8mm to 3mm, and they retain good light transmission (70–85%), reducing the need for artificial lighting in covered spaces.

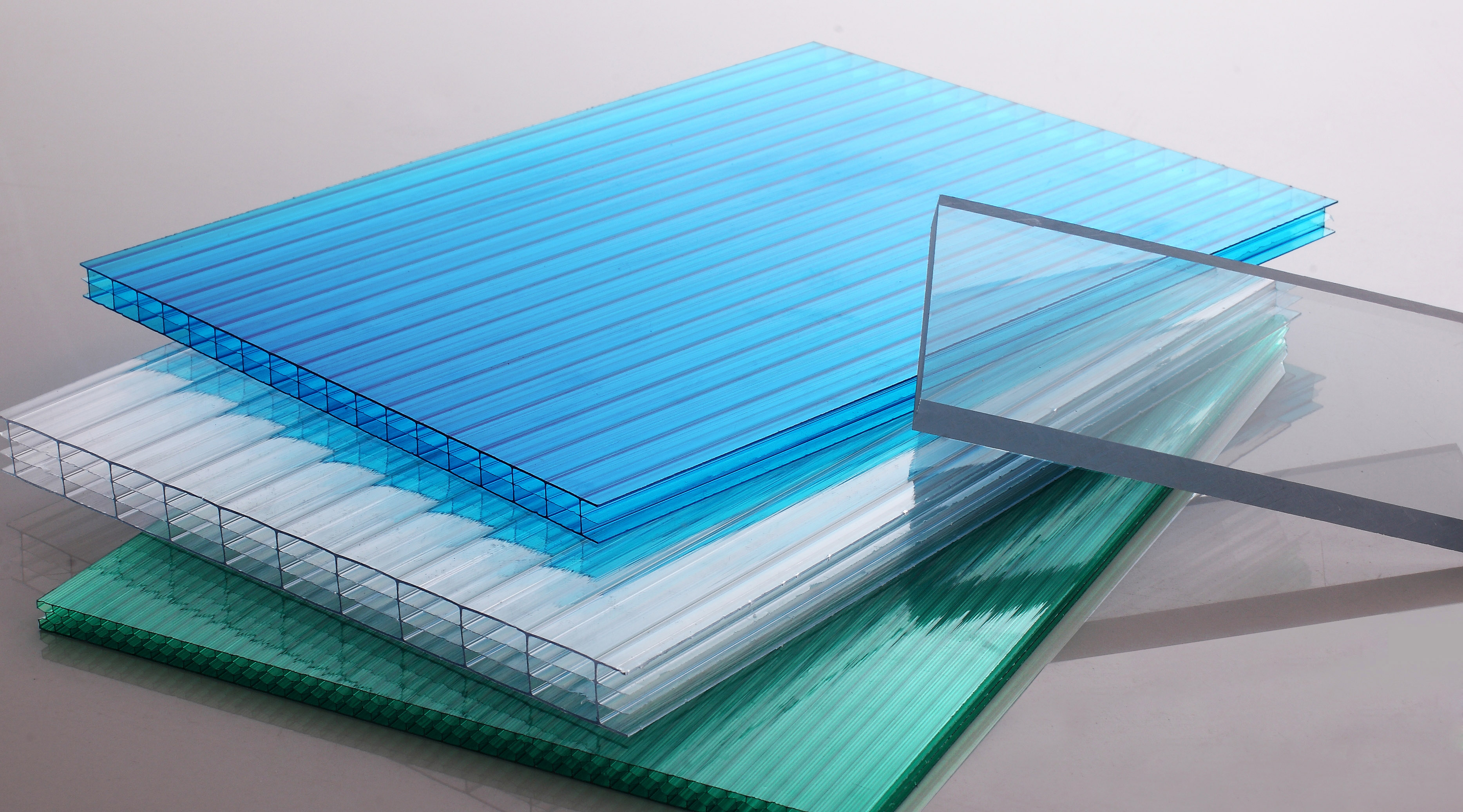

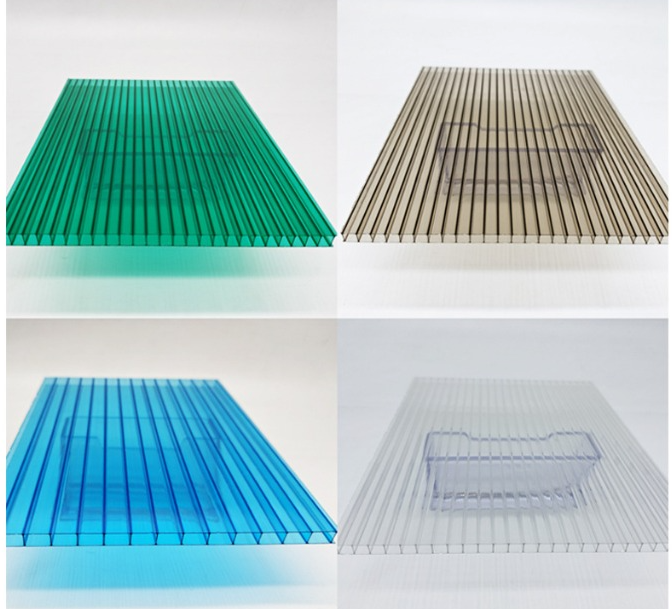

3. Multiwall (Hollow) PC Sheets

Multiwall PC sheets are characterized by parallel hollow chambers (typically 2–5 walls) separated by thin ribs, creating a lightweight yet robust structure. The air trapped in these chambers significantly improves thermal insulation, making them energy-efficient for applications like greenhouses, skylights, or partition walls. They also offer superior sound insulation compared to solid sheets. Available in thicknesses from 4mm to 40mm, multiwall sheets combine high impact resistance with reduced weight—up to 70% lighter than glass of the same size. Their rigidity suits large spans, such as warehouse roofing, while their transparency (60–80%) supports plant growth in horticultural settings.

4.Plug Pattern PC Sheets

PC sheets feature surface patterns (e.g., prismatic, matte, or dotted) designed to diffuse light, reducing glare while maintaining privacy. The textures scatter light evenly, making them ideal for lighting diffusers in offices, schools, or retail spaces. They also hide minor scratches, ensuring a consistent appearance over time. Applications include signage, ceiling panels, and decorative partitions, where aesthetics and light control are prioritized. Despite the texture, they retain good impact resistance and weatherability, suitable for both indoor and outdoor use.

5. Embossed PC Sheets

Similar to textured sheets but with deeper, more pronounced patterns, embossed PC sheets offer enhanced grip and slip resistance. This makes them suitable for flooring in industrial settings, ramps, or walkways where traction is critical. The embossing also adds visual interest, used in decorative facades or furniture panels. They maintain PC’s core properties—durability and chemical resistance—while combining functionality with design flexibility.

6.U Lock PC Sheets

U lock sheet, usually made of polycarbonate, features a unique U - shaped locking design. It ensures easy and secure installation without drilling, effectively solving issues like wind pressure, thermal expansion, and has excellent waterproof and thermal insulation properties.

Each PC sheet structure leverages polycarbonate’s inherent strengths—transparency, impact resistance, and UV stability—while addressing specific needs like insulation, weight, or light management. From protective barriers to energy-efficient greenhouses, these variations ensure PC sheets remain a go-to material for innovative and practical solutions.